At present, the four process cutting machine is the most cost-effective CNC woodworking cutting equipment. It is equipped with four spindle motors, composed of four main axes, which are combined to complete the cutting and carving of many basic panel furniture styles. The spindle control is the core of the operational efficiency of this equipment.

Four process spindle motor

Traditional usage method one:

using a frequency converter to divided into four circuits and controlling the spindle motor through a contactor for time sharing. Switching to the next motor only after the motor has completely stopped, resulting in long waiting times, low production efficiency, and complex wiring and debugging.

Schematic diagram of 1 frequency converter operation

Traditional usage method two:

Each spindle motor is connected to a frequency converter, can achieve synchronous real-time switching control, but it will increase equipment costs and occupy more space in the control box, affecting the heat dissipation performance of the control box. Simultaneously locating the fault point is relatively cumbersome.

Schematic diagram of four frequency converters working

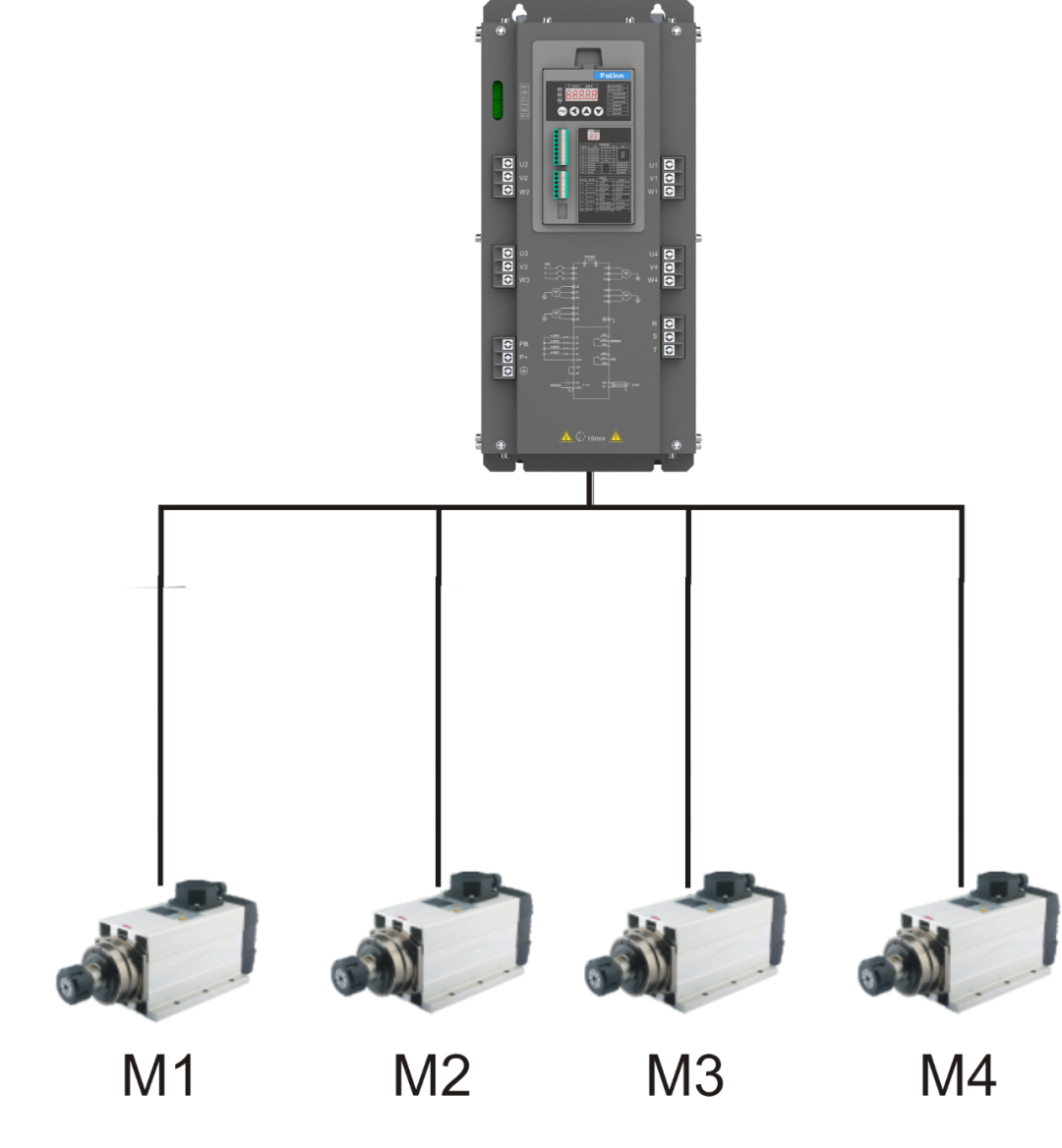

In recent years, four process CNC cutting machines have become increasingly popular in the market, and spindle control technology has been constantly updated and iterated. Folinn has developed the H440 series of exquisite multi drive controllers, which perfectly solve the problem of four process switching. It has achieved real-time control of four spindle motors by one controller, seamless connection and fast switching. When one spindle is processed, the other one immediately starts processing. No need to wait, truly achieving smooth spindle switching in 0 seconds.

H440 working diagram

Field application

At the same time, due to the high integration of the H440, it reduces peripheral wiring, saves contactors, and built-in motor parameters no need to debugging, making wiring easy to use. It can quickly locate the fault point and improve the overall efficiency of the machine. While reducing equipment costs, it greatly improves production efficiency.It is currently the best choice for spindle control of CNC four process cutting machines.