H7 series AC drive is a new generation of ultra-high performance intelligent vector drive independently developed by our company based on the industrial application requirements of high stability, high performance and easy debugging. It is suitable for asynchronous motor, permanent magnet synchronous motor, synchronous reluctance motor, etc. The system has accurate speed regulation, large low-frequency torque and fast load response. It can realize various functions such as spindle positioning, rigid tapping, thread cutting, low-speed reaming and so on.

Introduction

The spindle performance of CNC machine tools is directly related to the driver. The ordinary frequency inverter spindle only has speed control, but lack in the low-speed torque and response speed. Although the frequency inverter has the spindle positioning function, it can only do limited point positioning and cannot do position interpolation. Although some synchronous servo spindles have good low-speed performance and fast response, they have weak magnetic field at high speed and high cost, especially in high-power machines. Therefore, asynchronous servo spindle will become the mainstream of the market.

H7 series high performance motor driver

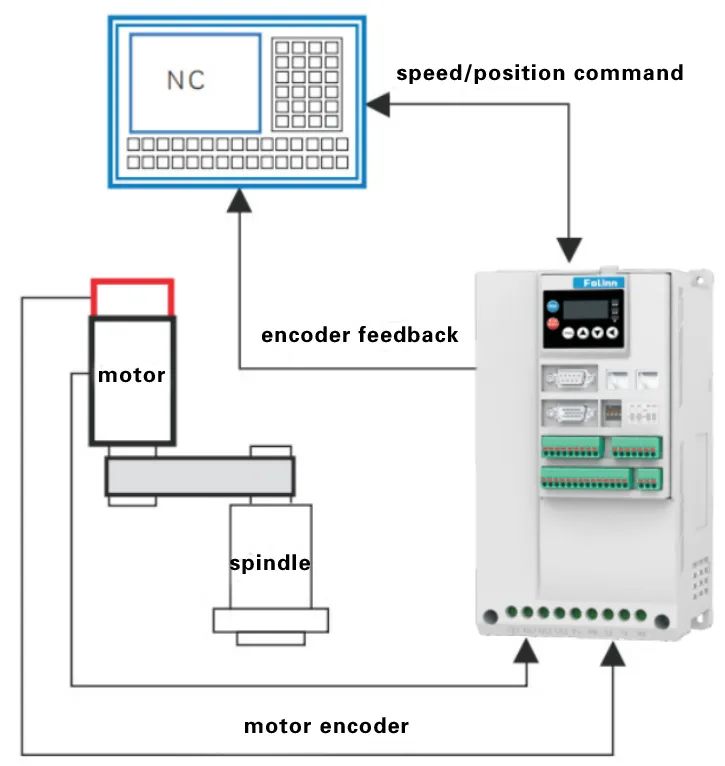

System Introduction

H7 spindle servo driver has accurate speed regulation, large low-frequency torque, strong load response ability and accurate position control, which makes up for the shortcomings of variable-frequency spindle and synchronous spindle. It can easily realize various functions such as spindle positioning, rigid tapping, thread cutting, low-speed reaming and so on. H7 spindle servo driver adopts advanced closed-loop intelligent vector control, detecting speed and position through the built-in encoder of servo motor, and feeds back the encoder signal to the system at the same time, so as to save spindle encoder.

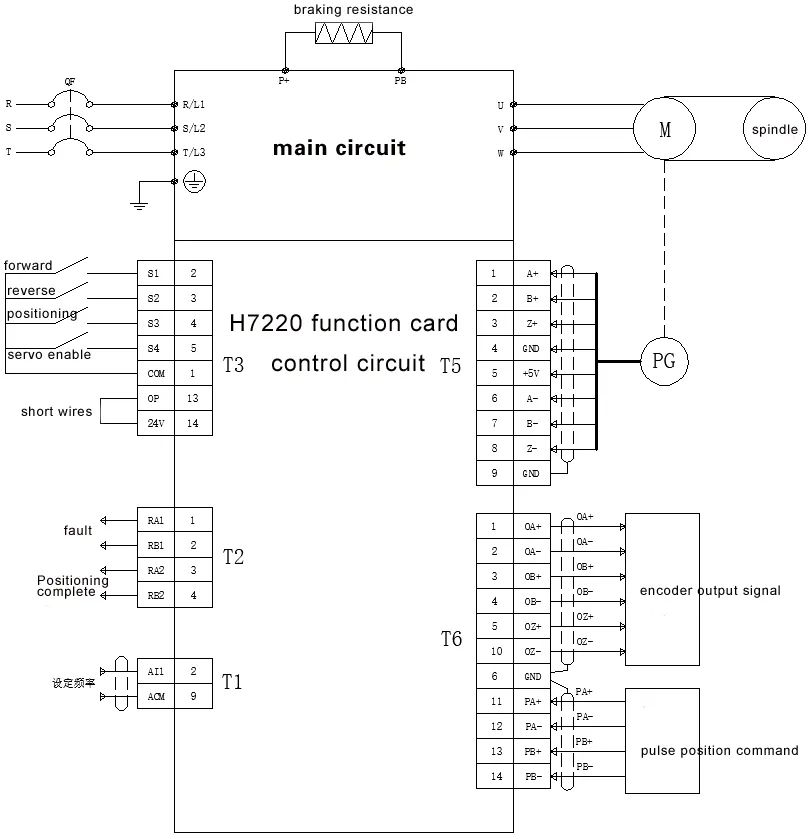

Electrical Schematic Diagram

Debugging Steps

1.closed Loop Self-Learning

1.1 Factory reset:P01.11=2

1.2 Set: closed loop intelligent vector

1.3 Set:P02.18=Max. frequency;

P05.08=upper frequency;

P06.11=motor rated power;

P06.12=motor rated power;

P06.13=motor rated freuqncy;

P06.14=motor rated current;

P06.15=motor rated speed;

P06.17=number of motor poles;

P14.00=Encoder type (0: no; 1: ABZ; 2: rotary transformer, power off and power on again after setting);

P14.01=encoder resolution;

1.4 Motor self-learning: Set P06.00 = 1, press the "RUN" key on the keyboard, the motor starts complete self-learning, and the motor runs. After the motor stops, press the "STOP" key, the self-learning is completed.

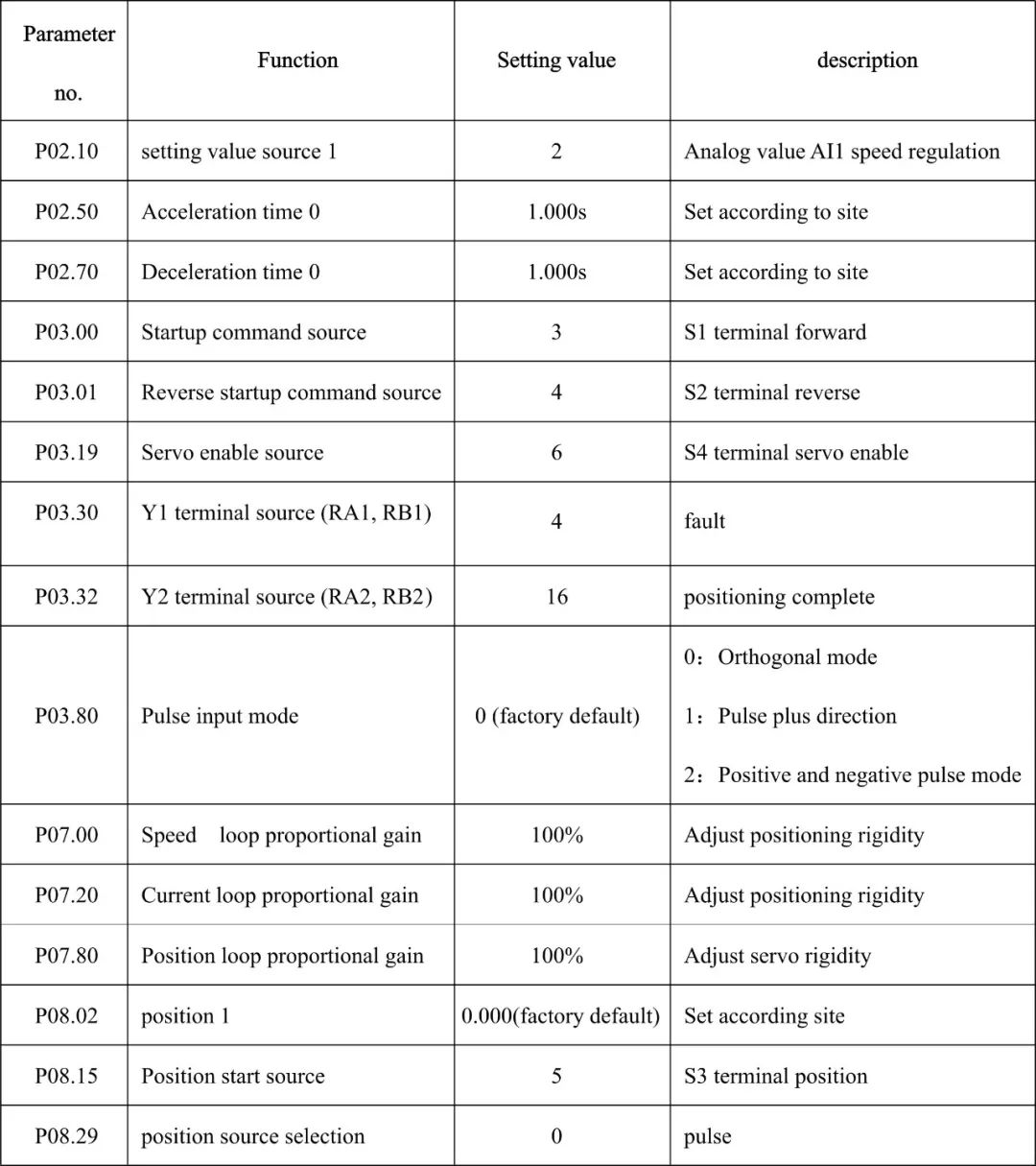

2.Set Parameters

Method of setting positioning position: when the driver is powered on and stopped, manually rotate the spindle to the position to be set, and then check the data of P10.82 (encoder angle), setting the data to P08.02.

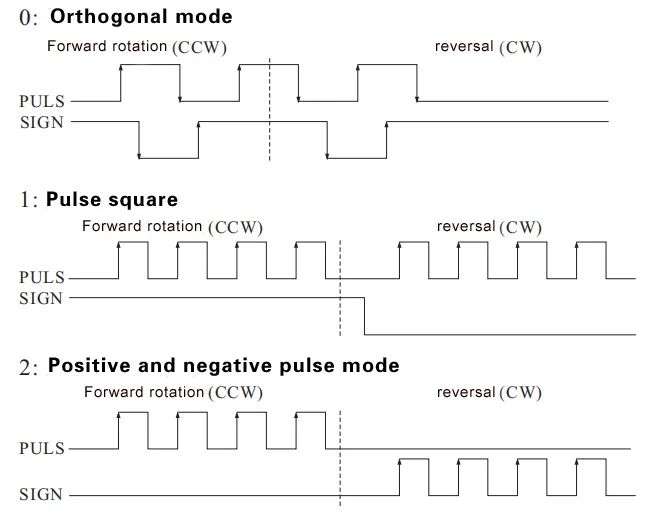

3. Pulse Input Mode

4. System Control

After the above steps are completed, the system controls the forward rotation, reverse rotation, speed regulation, positioning and pulse control of the driver.

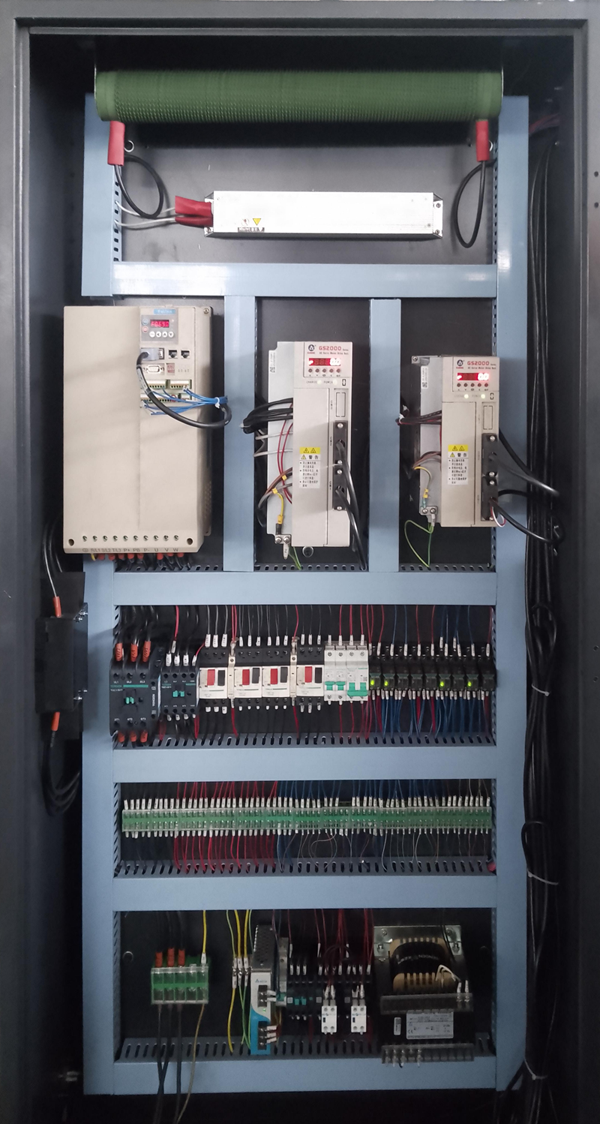

Site Photos

H7 driver application site

Application site

Conclusion

H7 series driver is based on vector control with top performance. The torque performance under open-loop control exceeds that of closed-loop control in the industry. It also provides pulse servo control function card and a variety of optional cards, which can be perfectly applied to servo positioning applications. The built-in PLC function greatly expands the scope of use, reduces the application cost, and can quickly adapt to different application sites.

About Us

Zhejiang New Folinn Electric Co., Ltd., referred to as Folinn Electric, was founded in 1994. It is located in Wenling, Zhejiang, a young city on the coastline of China and a famous advanced manufacturing base in the Yangtze River Delta. The company focuses on inverter manufacturing, and its market share has always been in the forefront of the industry. It is one of the few professional inverter manufacturers in China that integrates R & D, production and sales.

The company has 270 patented technologies and 21 software copyrights; the total construction area of its own workshop is 35,000 square meters. Three major R & D centers have been established in Taizhou, Hangzhou and Germany. The sales network and after-sales service agencies have been distributed in major provinces, cities and autonomous regions in the country, and are exported to Europe, America, Southeast Asia, the Middle East and other countries. After nearly 20 years of leaping development, it has been rated as the "Top Ten Domestic Low-Voltage Frequency Converter Brands" and "Zhejiang High-tech Enterprise" for many consecutive years.