1.ntroduction:

In the north, boiler heating is related to the daily work and life of thousands of households, especially in the large-scale central heating system, which has high requirements for constant pressure and constant temperature control and reliability. In the traditional boiler water level control system, the feed pump is running at a constant speed, and the flow control is realized by adjusting the regulating valve and the reflux branch in the water pipe. These two methods all have obvious defects. When the regulating valve is used, the pressure at the outlet of the water pump will rise and the pressure difference between the two sides of the valve will increase due to the reduction of the opening of the valve. When the valve is increased to a large extent, it will not only cause energy waste, but also increase the vibration and wear of the water pump, thus shortening its service life. A large amount of water reflux will also cause energy waste when the reflux branch is used for adjustment.

2.System requirements

1.Three boiler control, circulation and make-up systems

2.Each boiler has a blast and induced air system, the basic requirements are constant pressure control, and some requirements are constant pressure and constant temperature control

3.Full automatic and partial single control is required

4. It is required to be able to maintain part of the system and work continuously

5. Have control room with centralized monitoring system

3.System scheme

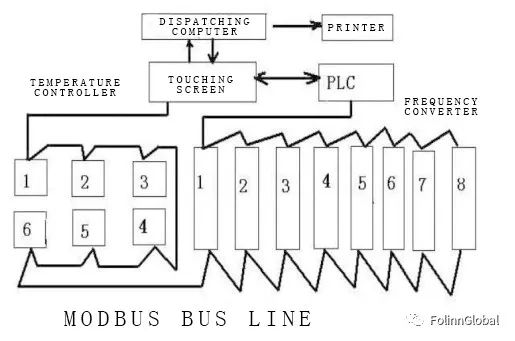

The system diagram is as follows

1. Inverter: 8 sets of BD330 series inverter, from 22kw to 200kw.

2. PLC: Siemens S7-300 is selected. Due to the powerful processing function of Siemens human-machine interface, most functions can be realized through touch screen

3.Human machine interface: Siemens human machine interface, which can realize data processing and operation. The relevant mathematical model is built in the rich processing instructions inside the human machine interface.

4.Low voltage apparatus is mainly used for protection and switching, which is controlled by manual and PLC. EA series is selected for air switch and SC-E series for contactor.

5.Fuji PXR4TE series temperature controller with Modbus Communication is selected.

Conclusion

The system makes full use of the powerful integration function of Siemens human-machine interface, and organically combines PLC, frequency converter and upper computer of temperature controller to achieve data sharing and control integration.

4.Frequency converter working status

The frequency converter is set through the input and output terminals connected with the external circuit, with two states of manual and automatic, the manual working state is regulated by the potentiometer to set the frequency, and the automatic working state is controlled by the output signal of PLC.

In practical application, the system has high degree of automation, intuitive display, obvious power saving effect and extended equipment life.

5.The control system of blast and induced air for frequency control of boiler

Introduction: in the whole heating system, the air volume of the blower and induced draft fan of the boiler also changes frequently, since the air volume changes frequently, the air volume needs to be adjusted frequently, in the old system, the air volume is changed by adjusting the valve. The boiler is far away from the valve, so it is inconvenient and improper to adjust. Too much air volume will waste of heat energy because excessive oxygen content in the air, and if air volume is too small, the residual carbon powder of cinder exceeds the standard and wastes coal, therefore, to improve the control level and ensure that the air oxygen content and coal residual carbon powder meet the standard, the air volume must be effectively adjusted, and the adjustment mode must be convenient, sensitive and reliable.

1。In order to improve the control level of the air volume of the boiler and achieve the effect of energy saving, it is the first choice to adjust the air volume by using the frequency control method. The application of frequency control technology can adjust the speed of the blower and induced draft fan at any time according to the change of gas consumption, reduce the pollution of noise to the environment, reduce the waste of energy, extend the service life of the equipment and save the maintenance cost.

2. Principle of fan speed regulation

2.1 Fan is a kind of square torque load, its basic parameters are:

①Air volume Q: air flow through the fan in unit time

②Wind pressure H: when the air flows through the fan, the total energy given to each cubic meter of air by the fan is called the total pressure Ht (Pa) of the fan, which is composed of static pressure Hd and dynamic pressure Hg, that is, Ht = Hd + Hg

③Power P: total effective power of the fan, Pt = QHT

④Efficiency η: fan air power divided by fan shaft power

2.2Fan characteristic curve

-Q curve: the relationship between air pressure and air volume when the speed is constant

P-Q curve: the relationship between power and air volume when the speed is constant

η - Q curve: efficiency characteristics of fan when rotating speed is constant

The H-Q curve under different speed control is shown in Figure 1: it can be seen from hydrodynamics that: P (power) = Q (flow rate) × H (pressure)

Q/Qe=n/ne

H/He=(n/ne)2

P/Pe=(n/ne)3

Qe: rated flow of fan

He: rated pressure of fan

Pe:rated power of fan

ne:rated speed of fan

It can be seen from the above formula that if the efficiency of the fan is certain, when it is required to adjust the flow Q to decrease, the rotating speed n can be reduced in proportion, and the output power P of the fan is reduced in cubic relation. That is to say, the power consumption P of the fan motor is approximately cubic to its speed n.

2.3 Wind resistance characteristics of pipe network

K=R*Q2

When the wind resistance characteristics of the pipe network remain unchanged, the relationship between air volume and ventilation resistance is: k = R * Q2

K:Ventilation resistance, unit ( Pa)

R:Wind resistance, unit (kg / m3)

Q:Air volume, unit (m3 / s)

According to the relationship between air volume and ventilation resistance, the characteristic curve of air resistance is parabola.(as shown in the R curve in Figure 1)

2.4Energy saving principle of fan

The relationship between speed and frequency of three-phase asynchronous motor is: n = 60F (1-s) / P

When the power frequency of the stator winding is changed, the speed of the motor can be changed, just the air volume can be adjusted, therefore, adjusting the speed of the motor can adjust the power of the input fan accordingly, so as to avoid the power consumed on the damper when the damper regulates the air volume.

Fig. 2 shows the relationship between air volume and power when the fan passes through the inlet baffle and frequency conversion control.

3. Design of frequency control system for induced draft fan

In the frequency control of the induced draft fan of the boiler, the section speed function of the inverter is used to automatically adjust the frequency of the motor according to the different working conditions of the boiler, so as to achieve the purpose of regulating the induced air volume.

This boiler is a negative pressure combustion boiler, if the furnace pressure is too high, the flame may spray out and damage the equipment or burn the personnel; if the negative pressure of the furnace is too large, too much cold air will be inhaled, which will reduce the temperature of the furnace and increase the heat loss.

The boiler shall be started slowly, and the starting process is as follows:

①Water system inspection

②Start induced draft fan

③Start the boiler. At this time, the boiler automatic control system starts the blower to purge the furnace and air duct

④During the ignition process, the electrode produces high-voltage electric spark, the fuel combustion booster starts to ignite, the burner solenoid valve is opened, the fire is lit, and the flame monitor starts to work. If the combustion is normal, delay for one minute, start the high fire solenoid valve and start the high fire. After the high fire is monitored to be normal, it will turn into the normal combustion stage

⑤According to the steam consumption, the boiler repeatedly switches between the big fire and the small fire

During the operation of the boiler, the automatic control system of the boiler automatically adjusts the opening of the inlet baffle plate of the blower to adjust the blast volume according to the different working conditions of the large and small fire electric valves, the induced draft fan adjusts its air volume by manually adjusting the size of its damper, considering the actual operation and investment cost of the boiler, we use the section speed function of inverter to transform the frequency conversion and speed regulation of the induced draft fan of the boiler.