Abstract: This paper introduces the application of Fuling frequency converter in gantry crane, and discusses the control system and functional requirements of gantry crane and the superior performance of Fuling bd550 series frequency converter in gantry crane. Key words: Folinn inverter gantry crane

1、Overview of Folinn BD550 frequency converter

Folinn BD550 high performance vector frequency converter is a special frequency converter specially designed for the lifting industry. Its main characteristics are large starting torque, low impact current, stable low-speed speed speed and low motor noise. It is widely used in lifting loads such as crane, tower crane, gantry crane, electric gourd, elevator and winch, and has been unanimously recognized and praised by users.

2、Inverter selection

1. Gantry crane host

The gantry crane is required to operate stably when lifting and lowering heavy objects, and the starting torque of the frequency converter is required to be large, and there shall be no sliding hook. Therefore, the frequency converter must be selected by expanding a power level than the motor.

For example, if the power of the main motor is 37KW / 380V, bd550-0450-4 (45KW) is selected as the frequency converter.

When the suspension bridge is lowering heavy objects, the motor is always in the power generation braking state, and the electric energy sent by the motor is fed back to the frequency converter through the cable, so as to increase the DC bus voltage of the frequency converter. Therefore, the frequency converter must be equipped with control unit and braking resistance. The excess electric energy generated by the motor must be consumed to prevent the frequency converter from generating overvoltage protection, so that the equipment can not be used normally. Since a large amount of regenerative electric energy will be generated when the weight is lowered, the modeling of braking unit and braking resistance shall be selected according to the two-step amplification of frequency converter of the same specification.

2. Gantry crane traveling motor

In case of one frequency converter with multiple motors (crane moving motor). The rated current of the selected frequency converter shall be the sum of the rated current of the motor multiplied by more than 1.2 times. In mobile applications, the acceleration and deceleration time of the frequency converter is required to be relatively fast. If the power of the frequency converter is small or there is no margin, the frequency converter will easily generate an alarm.

During the fast deceleration of the frequency converter, the motor is always in the power generation state, so the frequency converter must be equipped with control unit and braking resistance. The excess electric energy generated by the motor must be consumed to prevent the over-voltage protection of the frequency converter from making the equipment unable to operate normally. The braking unit and braking resistance shall be modeled according to the first gear of the frequency converter with the same specification.

3、 Wiring diagram and parameters

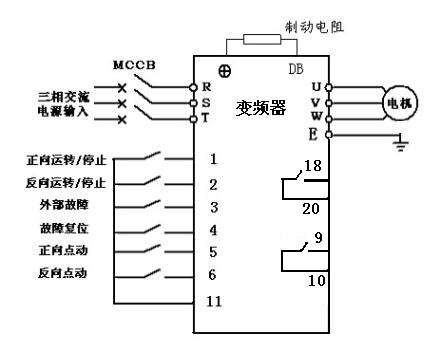

Wiring diagram

Parameter setting

A1-2=2 No PG vector control mode

B1-1=0 The operating frequency command comes from the keyboard

B1-2=1 The operation command comes from the control terminal

C1-1=5 Acceleration time

C1-2=5 Deceleration time

C1-10=0 Acceleration / deceleration time setting unit: 0.1s

E1-04=50.0,E1-06=50.0 Basic frequency of motor

H1-1=1 Forward running

H1-2=2 Reverse operation

H1-3=15 Emergency shutdown

H1-4=14 Abnormal reset

H1-5=12 Forward inching

H1-6=13 Reverse jog

H2-1=0 In operation

H2=2=10 Fault alarm

Precautions during commissioning:

1. Traveling crane and gantry crane are special equipment, and their operation specifications are very strict. Operation and maintenance must comply with the specification requirements of special operations.

2. The starting frequency and stopping frequency of the frequency converter must be consistent with the braking frequency of the mechanical holding brake to avoid the frequency converter jumping protection or sliding hook falling during starting and stopping. DC braking can also be added during starting and stopping to avoid the cage falling.

4、 Advantages of using frequency converter:

1. Soft start

Compared with power frequency starting mode, bd550 frequency converter control can reduce the vibration and impact of electrical and mechanical parts and make the lifting very stable.

2. Soft parking

Cooperate with the braking unit to brake stably and accurately without "sliding".

3. High starting torque

High performance vector control mode is adopted, the torque is adjustable, and stable high output torque is provided in low frequency band.

4. Safety and reliability

Universal uses frequency conversion speed regulation to realize stable operation of motor, improve operation efficiency, improve overload operation, eliminate starting and braking impact, reduce electrical maintenance and reduce electric energy consumption. At the same time, it has perfect safety protection functions, such as over-current, over-voltage, over torque, under voltage and input phase loss protection, as well as overtemperature, overload and motor fault protection of frequency converter, so as to ensure the reliability and safety of the whole electronic control system. Stepless speed regulation technology effectively solves the transmission impact of the mechanism and prolongs the service life of gears, rollers, bearings and racks.

5. Improve equipment service life and reduce equipment maintenance cost

The use of frequency conversion speed regulation limits the starting current of the equipment within the rated range, eliminates the impact on the power grid, incoming transformer and machinery when the original power frequency rises, greatly improves the service life of these electrical equipment, reduces the maintenance cost, and brings long-term benefits to the enterprise.

6. Good economy

(1) High efficiency; When using the relay control, because the speed rises too fast, it often needs repeated start and stop to complete a project task, and the use of frequency conversion speed regulation can be in place in one step.

(2) Energy saving; The speed and power of the elevator are higher, but compared with traditional products, the energy consumption is reduced by more than 20%.

(3) Equipment investment and maintenance costs decreased. For the same type of non speed regulating elevator, the gear, brake disc and several contactors shall be replaced at least four times a year. With this technology, the gear can be replaced by 50%, the service life of the rack can be doubled, and the service life of the brake can be up to ten years, which not only saves the working hours occupied by maintenance, but also saves considerable maintenance costs every year.

5、 Conclusion

The application of modern advanced AC frequency conversion speed regulation technology in elevator electric drive system not only makes the design of the whole electrical system of crane, gantry crane and other lifting industries simple and reliable, and the whole system is always in safe operation state, but also can quickly eliminate system faults through the fault query function of frequency converter. In the process of starting and stopping, the impact between mechanical systems can hardly be felt, which greatly improves the stability of the elevator in the operation process, saves a lot of electric energy for the enterprise and society, and greatly improves the work efficiency. Compared with the traditional construction elevator, the efficiency is increased by 30% and the energy consumption is reduced by 30%. Good comprehensive benefits are obtained and praised by customers. Therefore, variable frequency speed regulation has good popularization and application value in the whole hoisting industry.