Application of BD330 series frequency converter in double frequency conversion wire drawing machine

This text summarizes the advantages of BD330 series inverter and BD1000 inverter in the debugging and application of the water tank double frequency fine drawing machine of a wire drawing machine factory in Nantong. With the continuous improvement of process requirements, the requirements of wire drawing machine system for variable frequency winding are higher and higher

lBrief introduction of wire drawing machine

As an important equipment in the production of metal wire rod, the main function of wire drawing machine is to draw all kinds of wire rod into the required specifications of fine wire.From the working form and mechanical structure, it can be divided into straight in type, looper type, water tank type (also known as double frequency conversion wire drawing machine), etc. For different precision and specifications of products, different metal types can choose different specifications of wire drawing machinery. For the wire and cable manufacturing enterprises with copper and aluminum substrate, the double frequency conversion control fine drawing machine is widely used, while for most steel wire manufacturing enterprises, according to the steel characteristics, the direct wire drawing machine and water tank wire drawing machine are more widely used, the cost of equipment is low, the traditional water tank wire drawing machine has a large market share, based on the advantages of inverter, the frequency converter is widely used in the transformation of wire drawing machine equipment.

l Process introduction of double frequency converter wire drawing machine

lProcess description

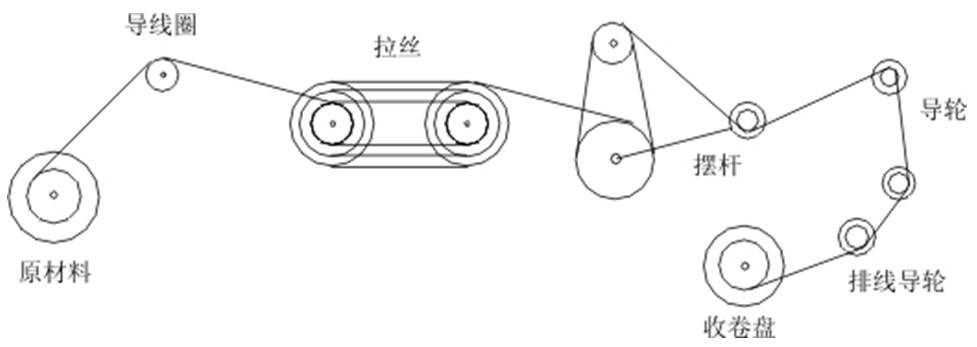

It mainly includes several processes of setting out, drawing and rewinding.

Process requirements and debugging plan

lProcess requirements

The customers are manufacturers who use their own production of water tank wire drawing machine machinery , but also are the final customers of wire drawing machine machinery. Water tank wire drawing machine with 19 mould, 6mm incoming wire and 0.3mm outgoing wire. It has the following requirements:

◆Start smoothly. It is required that the 0.3mm iron wire material shall be stable and continuous in the process of winding start, acceleration, deceleration, etc;

◆The stable operating speed is 900m / min. (the operating frequency of empty volume is 45Hz, and that of full volume is 20Hz)

◆During the operation, the swing of the swing rod is small and stable. (frequency change rate caused by coil diameter change is within 1Hz)

◆Emergency stop function (the whole system can stop within 2S, and keep the line)

◆It has the function of automatic detection of disconnection. (detect the disconnection function according to the position of the swing bar)

lInverter selection

Host: BD330(high performance general type inverter)